2022-08-23

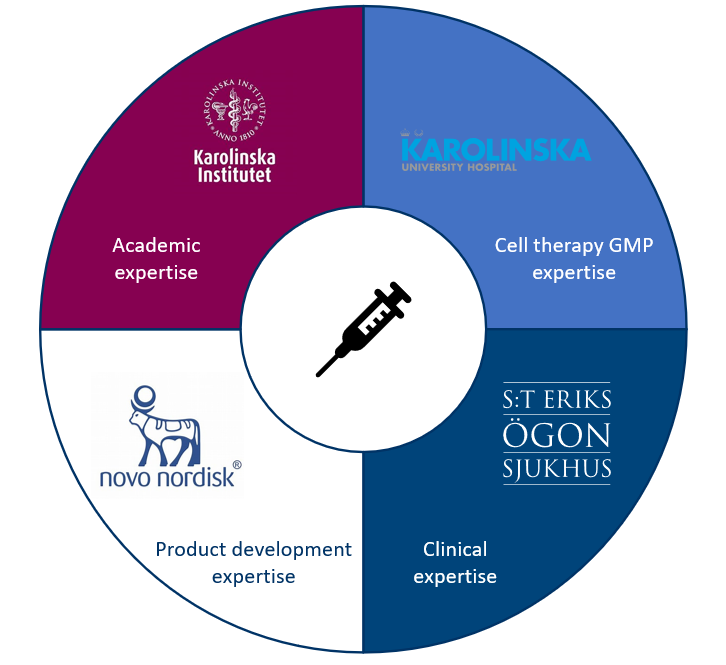

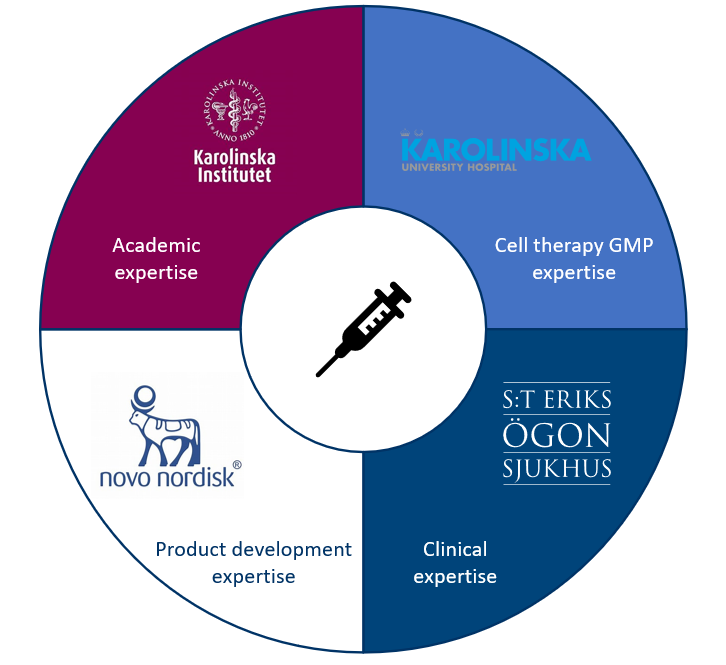

The Novo Nordisk/Karolinska Institutet/St Erik/Vecura model

Written and lived by Dr. Heather Main, Communications ATMP Sweden

How long does product development take?….does it ever end? Those who know I’m ‘not just a communicator’ know that I have spent the last 4 years working in Fredrik Lanner’s group at Karolinska Institutet and Vecura at Karolinska University Hospital towards translating a research grade protocol for human pluripotent stem cell derived retinal pigment epithelia (hPSC-RPE) to a GMP grade Advanced Therapy investigational Medicinal Product (ATiMP). 4 years before my time the Lanner lab had begun developing research grade hPSC-RPE in collaboration with Anders Kvanta from St Erik Eye Hospital/Karolinska Institutet, Stockholm, and 2 years before my time my GMP buddy Mona Hedenskog began with GMP derivation of Sweden’s first GMP hPSC line with Katrin Markland as Production Manager at Vecura, Karolinska University Hospital, Stockholm.

With St Erik initially funding the clinical development, I entered the project at the stage where ‘a few reagents need to be adapted’ so we could start GMP manufacture….Katrin from Vecura would laugh….did laugh. In retrospect we had no idea what we were getting into. GMP translation of a cell-based therapy is overwhelming. As an academic, you cannot begin to comprehend what it takes till you set off on that dark forest path. The 13th of December 2021 we harvested our first GMP batch, the 11th of April 2022 our fourth. What we have been through is difficult to explain, physically, psychologically…if you have not qualified raw materials, written a batch protocol, qualified equipment, validated a process, sat with your hands in the A environment and passaged and harvested cells that will be injected into a patient….(and then pressed your gloved fingers onto an agar plate!), you cannot understand what it takes to get that cellular therapy pharmaceutical into the freezer. And for the most part you don’t need to. But to give you an idea, the majority of the work in getting into patients starts when you are done in the research labs.

2 years ago, we started collaborating with Novo Nordisk to make our ‘bench to bedside’ product an FDA compliant ‘bench to reimbursement’ pharmaceutical. Academic products often aim for Phase I (the bedside), but in the absence of commercial expertise in Phase I development the IP, quality standards, regulatory compliance and scaleability are unlikely to create the package needed for the product to survive commercial development, questioning the relevance of the time and (tax payer) money used to get it to Phase I. This is no fault of the academic or clinician, whose are not intended to be commecial developers, but food for thought on what our true objectives are and where we may need to partner with competencies we do not have to achieve this.

Jacob Sten Petersen

Novo Nordisk was an early mover in the development of hPSC-ATMP medicines, first for treatment of Type I diabetes, aiming to provide an alternative to lifelong insulin treatment, that they themselves manufacture for approx. 50% of the global insulin market. Novo Nordisk established international partnerships to synergise their efforts with academic protocols and experienced cell therapy developers around the world. The first example of this was Malin Parmar’s dopaminergic neuron progenitor product, manufactured in collaboration with the Royal Free Hospital in London. The second, following international review, would be Fredrik Lanner’s hPSC-RPE protocol, the product I was responsible for adapting. I chatted with Head of Cell Therapy R&D Novo Nordisk, Jacob Sten Petersen, about their experience of working with our Karolinska Institutet/Vecura/St Erik Eye Hospital team.

“Novo Nordisk has decades of experience in the culture of mammalian cells for production of different proteins”, says Jacob. “This experience made the decision to move into cell therapy an ‘easy one to make’, though, as we know, making ‘living drugs’ means classical biologics purification, formulation and sterilisation steps cannot be performed, adding many levels of complications in selection of raw materials and aseptic processing. The analytical package is also orders of magnitude more difficult (larger), you’re unable to fall back on the purity and potency assays of classic biologics. We knew that timely success in this space would mean linking our expertise to other manufacturers experienced in cell therapy”.

While the Lanner/Vecura/Kvanta collaboration was making headway, the inclusion of Novo Nordisk into the project was an eye opener on the enormous value held in existing pharma who may have ‘no experience’ in ATMP but a wealth of experience in the manufacturing, quality and commercial thinking around pharmaceutical development, which is essential in ensuring the product is not only developed to make it to ‘the’ patient but to succeed in reaching and benefitting a global market of patients. A simple example….what does it say on the label of your ATiMP? Has your vial label been developed to comply with Swedish Phase I/II clinical trial or commercial approval through the FDA? “Linking diverse expertise where everybody is contributing their significant, important knowledge and everyone else is absorbing and valuing this knowledge with a ‘wow, it’s really nice you can contribute’ attitude, has made the Vecura, Karolinska, Novo Nordisk collaboration one of the best we have had”, says Jacob. “Everyone wants the same thing and listens to each other. All want to provide a treatment for patients that really need it. That’s the first priority.”

While the Lanner/Vecura/Kvanta collaboration was making headway, the inclusion of Novo Nordisk into the project was an eye opener on the enormous value held in existing pharma who may have ‘no experience’ in ATMP but a wealth of experience in the manufacturing, quality and commercial thinking around pharmaceutical development, which is essential in ensuring the product is not only developed to make it to ‘the’ patient but to succeed in reaching and benefitting a global market of patients. A simple example….what does it say on the label of your ATiMP? Has your vial label been developed to comply with Swedish Phase I/II clinical trial or commercial approval through the FDA? “Linking diverse expertise where everybody is contributing their significant, important knowledge and everyone else is absorbing and valuing this knowledge with a ‘wow, it’s really nice you can contribute’ attitude, has made the Vecura, Karolinska, Novo Nordisk collaboration one of the best we have had”, says Jacob. “Everyone wants the same thing and listens to each other. All want to provide a treatment for patients that really need it. That’s the first priority.”

There is a long history of collaboration between Fredrik Lanner and Anders Kvanta, which was able to smoothly connect to Vecura, strategically located in the same building as Fredrik’s lab. Novo Nordisk was then able to dock into a network primed for efficient translation, manufacture and patient delivery. Anders Kvanta had even been involved in a Novartis sponsored gene therapy trial where he delivered an AAV based gene therapy medicine to patients with Retinitis Pigmentosa and Luxturna for inherited retinal dystrophy. “All partners in this project have been very well aligned. We had one location, one review board, one CTA, good sync in terms of timelines/comments and great communication.” says Jacob, “Communication is essential with something so complex. It has been and continues to be a very tight and well-coordinated effort and more importantly that we all feel we are on the same team with the same priorities”.

Vecura was an essential part of this project. “Vecura is very experienced compared to other manufacturers, but they are not just a CMO/CRO” says Jacob, “the sharing of their knowledge and experience in a diversity of cellular therapies in a truly collaborative manner really makes this process relatively smooth. You can bring your own people and resources to the facility and accelerate your translation. The more you can facilitate translation and clinical proof of concept the more medicines and jobs will be created so important discoveries will get to those who need it”.

Agar plates from monitoring air, surfaces, gloves

I’m quite often telling people that Katrin Markland from Vecura is the star of our show, but that they are not allowed to poach her. Katrin has worked with Vecura now for over 12 years and was in different projects a QA or production manager. Katrin was the only person in all of our meetings who has ever been responsible for the development, manufacture and release of an ATiMP for clinical trial before. Known as ‘eagle eye’ Katrin I have been constantly amazed over the last 4 years at the ability of Katrin (and Jenny Enger QP) to have such a deep understanding of our process that they were able to question the smallest details (and sometimes big ones) to make a better product. I have developed an enormous respect for the abilities of QA/QPs in ATMP manufacture.

In our Novo Nordisk meetings representatives from different teams were often brought in for specific purposes. Katrin was highly respected and quite often it seemed that ‘Goliath’ was sitting pensively waiting to absorb ‘David’s’ wisdom, but Novo Nordisk brought with them a whole suite of expertise under guidance of Senior CMC Project Leader Michael Wagner Christiansen. Think device, cell count validation, product quality, requirements on raw materials (viral filter/irradiation), product purification, vial labelling as mentioned, container closure, stability (shelf life and in use), formulation, dosage and delivery homogeneity etc….there is a difference in decisions to be made for FIH versus commercial FDA compliance. “Novo Nordisk is investing a lot in hitting commercial compliance as early as possible and the collaboration with Vecura and the Karolinska has been a truly 1+1+1=5 towards producing a product that hits those criteria not normally controlled for in first in human ATMP clinical trials” says Jacob.

What have been the biggest challenges and most exciting advances for Novo Nordisk in working with hPSC derived pharmaceuticals? “The toughest part is that there is no approved product. There’s no blueprint. What is really required for quality/CMC/analytical packages? We’re building the bridge while we are walking on it. There’s incredibly high uncertainty and a need to be extremely agile” says Jacob. “Compared to biologics that can be sterilized and purified using classical downstream processing, there are many more analytical packages and raw materials for each step. The manufacture takes longer, in this case 11 weeks from thaw till harvest, there are more steps and thus more risk of things going wrong. There are also new supply chain issues for things that cannot be frozen and how to store and transport the product and I could go on….”

And how does it look for the future Jacob? “Collaborations as good as this one you do not throw away when you are done. We have many ideas on how to continue the collaboration, may it be other cell types or scalability projects,” says Jacob. “Novo Nordisk has the ambition to be leaders in hPSC-ATMP space and hopefully Vecura and the Karolinska are very important aspects of this.”

Filling the cell product

For me, I’m still recovering from those months of GMP manufacture. The 15th of June I fly out to Australia for some much-needed post pandemic family time. What I’d like to leave with you from my experiences of the last 4 years of being responsible not only for product development and manufacture of an hPSC-ATMP, but also for the development of the ATMP Sweden platform, is that no one person, organization or project knows how to develop an ATMP. Even to have expertise in ‘ATMP’ is quite diverse considering that someone with competence in the mRNA medicine space has more in common with recombinant protein manufacture than cell therapy manufacture.

To make Sweden ‘world leaders’ in ATMP we need to be humble of our own expertise. I feel so lucky to have had the opportunity to be involved in the Novo Nordisk, Vecura, Karolinska collaboration and have found the GMP for ATMP field to be an extremely exciting space with currently limitless opportunity for learning and exponential growth with currently few ‘experts’ in the diversity of critical areas. There are big challenges that we need to work on together right now to secure the future and potential of ATMPs for patients. Sweden’s track record of working together prime us to lead this space through truly collaborative intention and synergistic respect for the expertise of various stakeholders. It’s not time for competition, there’s more than enough opportunity to go around.