IndiCell

TECHNOLOGY SOLUTIONS FOR hPSC DERIVED CELL THERAPY MANUFACTURE

TECHNOLOGY SOLUTIONS FOR hPSC DERIVED CELL THERAPY MANUFACTURE

Our overall aim is to develop and consolidate a sustainable, collaborative and world leading innovation milieu (IndiCell) based on Individual cell therapy that will continue also after the end of this funding. IndiCell will derive state-of-the-art workflows addressing generic steps in the process of deriving iPSC therapies products using our own world-leading projects as models. Those workflows and IndiCell’s competence will decrease cost, labour, time and clear the regulatory path for future iPSC therapy projects in Sweden, in addition to lowering the threshold for innovations.

Coordinator: Lund University

Partners: Karolinska Institutet, KTH, BioLamina, AcouSort, MAGic BioProcessing, Skåne University Hospital, Karolinska University Hospital.

WORK PACKAGES

- Enabling patient specific cell procurement and bedside delivery.

- Reprogramming-in-a-chip: Cutting time, labour and cost of iPSC manufacturing.

- Cell sorting: Validate procedures for negative and positive sorting for safer cell therapy products.

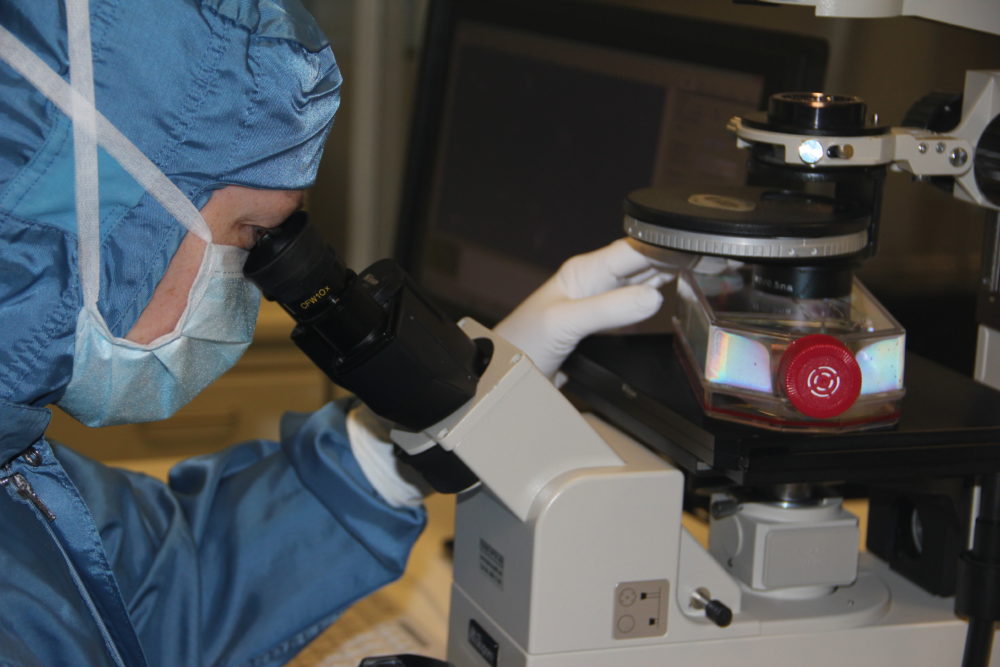

- Quality control methods: assess batch to batch variability and reduce the need for animal toxicology studies

- Innovation: Capturing potential for product development, commercialization and translation.

- Project management: Structure for the management, decision making, project follow-up, future and evaluation

Contact:

Scientific project leader – Anna Falk

Admin project leader – Paulina Pettersson

Website: http://indicell.se/

Road Map for setting the ethical and legal framework of stem cell based ATMP in Sweden

What are the processes in getting ATMPs manufactured and into clinical trial?